Events

Anglian Water – 23 January 2025 Winterton Holmes Works – Hardness Consumer contacts

Winterton Holmes works, situated in North Lincolnshire, is a ground water treatment works. On 27 August 2024. Winterton Holmes works was returned to supply following a period of five years and 17 days of being out of service for planned work. The company conducted sampling of the boreholes to meet the requirements of regulation 15.

Elsham works, also situated in North Lincolnshire, supplied both Winterton and Burton Upon Stath distribution zones whilst Winterton Holmes works was out of supply during the period July 2019 to August 2024.

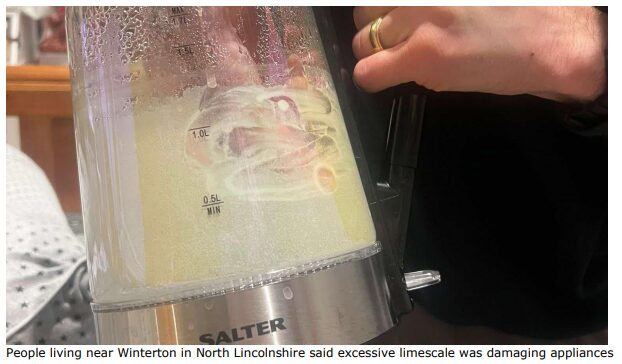

From September to December 2024, the company received 65 consumer contacts for hardness or the change in water supply. The company notified the Inspectorate of this event on 23 January 2025 following the receipt of greater than 100 consumer complaints, enquiries or contacts relating to hardness or changes in the water supply.

The company’s investigation concluded that the final water pH of the water supply was 0.2 pH units higher than when in supply previously. The company used the Langelier Saturation Index (LSI) model to show the water had changed from fairly stable to likely depositing/precipitating when changed from the Elsham to Winterton Holmes supply. An LSI value >0.5 is considered to be scale forming and the company found the LSI at Winterton Holmes works in 2018 was previously 0.67. Between August 2024 and 23 January 2025, when phosphate was not being dosed at the works, the LSI value was higher at 0.83.

The company deemed it acceptable to return the works to supply without phosphate dosing, which is used for plumbosolvency control of lead service pipes. The phosphate dosing remained offline for five months whilst the site was in supply. This approach did not align with good practice for maintaining protection against lead leaching from the distribution network. A recommendation was made for the company to ensure that phosphate dosing is treated as a critical control measure when returning any works to supply where there is a known lead risk downstream. Following the reintroduction of phosphate dosing, the LSI decreased from 0.83 to 0.77, also demonstrating its positive impact on the final water.

It was also noted that the company has, on previous occasions, relied solely on its website to communicate important messages to consumers. A recommendation was made for the company to review all its risk assessments for hardness and where changes in supply will result in a change of perceived hardness and therefore acceptability by consumers, an appropriate and proactive method of communicating these changes should be used to reach all impacted consumers.

Lessons for the industry highlight the need for more proactive communication strategies that extend beyond passive channels, such as company websites. In circumstances where supply changes may influence water hardness or consumer acceptability, robust risk assessments and management plans should be i Implemented in accordance with Section 86 of the Water Industry Act 1991, requiring water companies to evidence their understanding of any water quality changes resulting from their actions and the mitigation measures proposed.

Yorkshire Water – 18 February 2025 – Barnsley Repeat Clostridium perfringens detections

A 2-inch cast iron main, in Barnsley, was excavated for a live burst repair on 10 February 2025. A further repair on 17 February 2025 required a shut off, which was completed by a Yorkshire Water employee. Flushing was not possible from a hydrant downstream of the repair, so the company requested that consumers at a property on the affected main flushed their taps for 20 minutes. Samples from the upstream hydrant and consumer property contained Clostridium perfringens.

Sampling continued on a daily basis until 27 February 2025, with Clostridium perfringens detections from numerous properties. Boil water advice was provided on 24 February 2025 and rescinded on 1 March 2025. The company acknowledged that the flushing undertaken at a consumer’s tap was inadequate to generate sufficient turnover of the main. Flushing from a consumer tap can also drag sediment into the smaller pipes of the property, causing blockages and damage. It was also clear that the company’s risk assessment did not adequately include details of how to proceed when an end hydrant is not accessible. A recommendation was given for the company to include clear instructions for ensuring appropriate flushing points are available or installed if necessary. The company acknowledged that an appropriate sample could have been taken after the repair from a downstream property, but the issue was not escalated.

The incident highlighted the importance of ensuring that flushing is carried out effectively from appropriate points on the network rather than from consumer taps. Companies should ensure robust processes are in place to assess and manage risks following repairs, including appropriate flushing, sampling, and escalation procedures.

Wessex Water – detection of sum of PFAS in tier 3

A sample collected by Wessex Water in February from its Charlton works located in Wiltshire was found to have a ‘sum of’ PFAS concentration of 0.103 µg/L which is within tier 3 in accordance with the Inspectorate’s PFAS guidance. The most likely source of the PFAS is thought to be from historical airbases and firefighting foams. Whilst the detection on its own is not an indication of worsening of risk (due to the historical nature of the land usage) the Inspectorate introduced updated guidance in August 2024 which now considers the combined concentration of the named 48 PFAS parameters, the ‘sum of’ PFAS. The inclusion of the ‘sum of’ PFAS as a precautionary guideline value has been agreed with UKHSA and is world-leading with England and Wales having one of the most comprehensive PFAS monitoring strategies globally, ensuring consumers can have complete confidence in the safety of their drinking water.

At Charlton works, the majority of the water supplied from the works undergoes blending with another source however a proportion of the water is supplied to consumers, potentially putting these consumers at risk.

The updated guidance requires the company to take action to reduce the concentration of PFAS to be low tier 3 in the short term and implement a longer-term strategy to progressively reduce the PFAS risk.

Wessex Water submitted a PR24 scheme for catchment investigation, design and installation of dedicated treatment for PFAS at its Charlton scheme which was supported by the Inspectorate and a regulation 28(4) was notice served to ensure the delivery of the new treatment. The delivery of the new treatment system was due by 2035, in accordance with the company’s risk reduction strategy as the site was previously demonstrating concentrations of individual PFAS in tier 2.

Following the tightening of the PFAS guidance and the detection of ‘the sum’ of PFAS in excess of the tier 3 guideline value, the Inspectorate took further enforcement action requiring Wessex Water to take short term action to reduce the concentration of PFAS in the proportion of the unblended flow whilst the new treatment works is being delivered. Wessex Water are installing temporary GAC treatment on the unblended flow, which is due to be delivered by the end of November 2025, and have brought forward the delivery of the new treatment works to the end of 2030. The Inspectorate revised its improvement notice to take into account the need to install the temporary treatment and to bring forward the milestone of the delivery of the longer-term solution. The Inspectorate, in its assessment of the event, also made some specific recommendations to Wessex Water around the frequency and laboratory turnaround times for monitoring PFAS at Charlton and the other sources used for blending and to ensure that there is a documented and verifiable blending plan for the proportion of the flow which undergoes blending.

Water companies are reminded to ensure that their PFAS monitoring and mitigation strategies are kept under continuous review and should any sites be exhibiting a change of risk, in particular for ‘sum of’ PFAS that they act quickly to ensure that short term mitigations can be deployed or installed to reduce the concentration to below tier 3, whilst the longer term mitigation is implemented. Where companies are using blending as a mitigation for PFAS reduction, companies should ensure that these are being effectively monitored and that the blending can be verified.

South West & Bournemouth Water final water turbidity events – Wendron, Dousland and DeLank works.

In March and April 2025 South West & Bournemouth Water reported three water quality events which resulted in high final water turbidity from three water treatment works: Wendron, Dousland and DeLank. Whilst the initial causative reason for the events at these works was different, the root cause for the elevated final turbidity leaving the works for each event was the same. The high turbidity was a result of lime build up in the final water tank combined with a change in flow or level in the tank. Two of the works are covered by legal instruments for cleaning an inspection of water storage tanks and the other works tank had been cleaned 10 years prior and was due for inspection and cleaning this year. One of the events also resulted in a prolonged loss of supply from the works.

The Inspectorate made a number of recommendations following these events including that the company review the frequency of cleaning of works tanks to reduce the risk from lime build-up resulting in elevated turbidity leaving the works, and to undertake measures to review and improve lime dosing and mixing at all sites which utilise lime dosing to minimise the build-up of lime in works tanks.

The Inspectorate reminds companies of the importance of using a risk-based approach to determine the appropriate frequency for the inspection and cleaning of water treatment works tanks, especially where chemical dosing may result in deposition within the tank. Also, that companies should either mitigate or have control measures in place to prevent the risk of lime build-up in works tanks to prevent a potential elevated turbidity event from a works.