- Drinking Water 2024 – Summary of the Chief Inspector’s report for drinking water in Wales

- Foreword

- Water supplies and testing

- Compliance with standards

- Learning from compliance failures

- Learning from events

- Consumer contacts

- Asset health

- Water safety planning and risk assessment

- Raw water

- Poly and perfluoroalkyl substances (PFAS)

- Audit programme

- Recommendations

- Enforcement

- SEMD

- NIS

- Materials in contact with drinking water (Regulation 31)

- Research publications

- Whistleblowers

- Working with stakeholders

- Annex A – Number of tests carried out by companies

- Annex B – Compliance with standards

- Annex C – Compliance failures and events

Asset health

Treated water tanks and service reservoirs

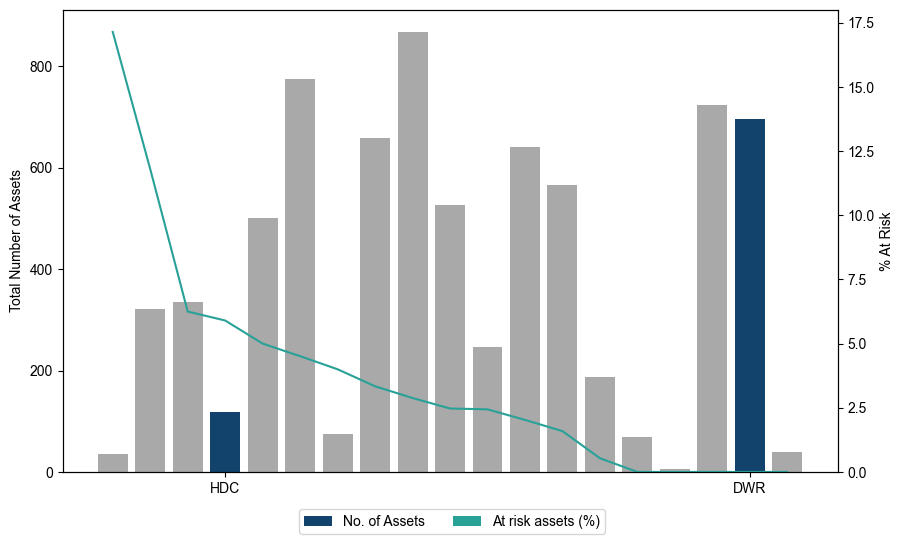

The Inspectorate remains committed to strengthening the integrity of service reservoirs and treated water tanks. In 2024, this initiative has included comprehensive audits of service reservoirs and ongoing scrutiny of the regulation 28(4) notices issued to both Welsh companies in 2022.

For Dŵr Cymru Welsh Water in particular, the impact of this notice is now fully evident. As of April 2025, all service reservoirs and treated water tanks have been removed from supply to enable a full drain down and inspection, with now none that are in service, exceeding 10 years between inspections. Some of the inspections are outstanding, however the Inspectorate expects these to be completed before these tanks are returned to supply, as part of the regulation 28(4) notice obligations. Dŵr Cymru Welsh Water should be commended for the efforts made to complete this important work to ensure every tank has undergone a full assessment within the past decade.

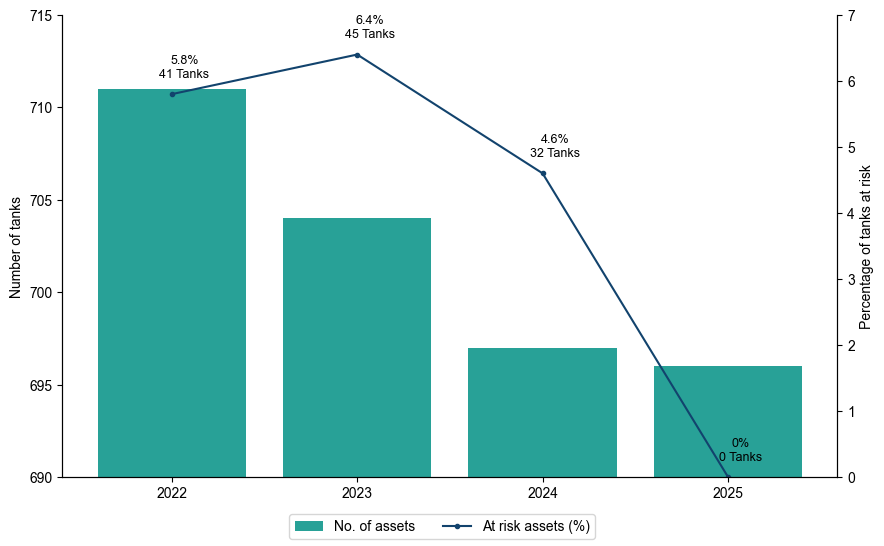

Figure 18 shows the good progress made by Dŵr Cymru Welsh Water, with no tanks in supply that have not been inspected within the past 10 years.

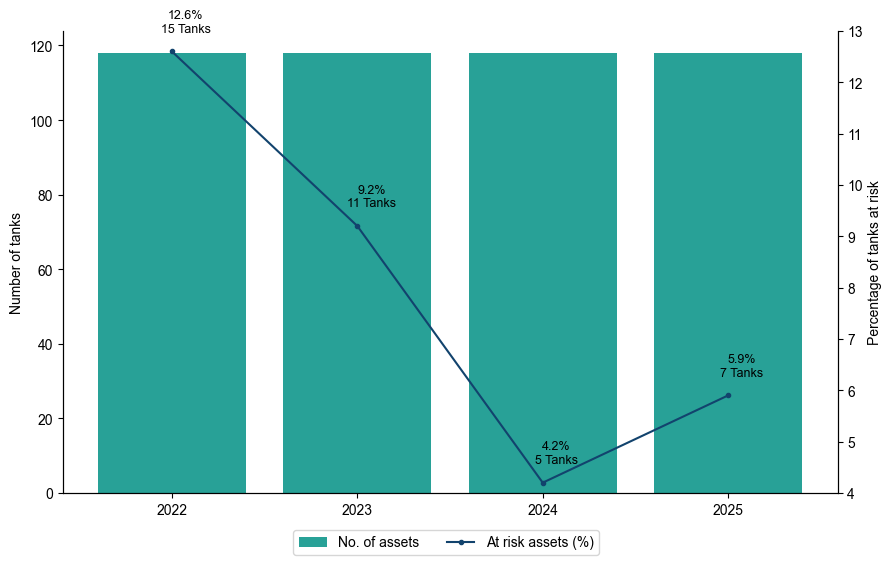

Figure 19 shows the progress made by Hafren Dyfrdwy. There are seven ‘at risk’ tanks which have not been fully inspected in the past 10 years, marginally more than in 2023. Three of these tanks are covered by separate regulation 28(4) notices and require a new tank to be constructed to enable the existing tanks to be removed from service. A short term measure in these notices is to conduct remotely operated vehicle inspections to provide information on current internal tank condition and integrity .

Granular activated carbon management

There have been several events in 2024 involving the breakthrough of taste and odour compounds at Glascoed and Talybont works as well as at an upstream works in Chester impacting a bulk supply into the Saltney water quality zone. In each case the management of taste and odour treatment, namely granular activated carbon adsorbers (GAC) and powdered activated carbon (PAC) dosing systems, has played a role in this breakthrough. Recommendations have been made to companies in response to audits and event assessments to address shortcomings in contemporary and historic GAC management practices. The contemporary adsorbance capacity of the GAC at works will define their ability to remove most taste and odour compounds where they are installed to mitigate taste and odour risks . This adsorbance capacity is impacted by several factors including the loading experienced at the site over time, the frequency at which the media has been historically regenerated and the length of time that the process water is in contact with the carbon. A common theme in the taste and odour events in Wales in recent years, is the failure of companies to appreciate the existing status of GAC adsorbance capacity, until the point at which it becomes overwhelmed by a rapidly developing raw water challenge. Examples include high solids loading, low adsorber media iodine numbers associated with excessive run-times between media regeneration, and a failure to adequately monitor and control empty bed contact times. A carefully planned and routine monitoring and intervention strategy for adsorbance capacity, contact time and associated adsorber performance metrics is therefore important in mitigating the recurrence of such events.

In addition to conventional GAC adsorbers, another option to increase a sites carbon adsorbance capacity is the dosing of powdered activated carbon (PAC) into the process stream. In several instances this operational intervention has not been effective in mitigating breakthrough of taste and odour compounds during events. In some cases operational triggers have not enabled a timely enough response. In other cases, insufficient dosing capacity or contact time have limited the effectiveness of the dosed PAC. Companies are trialling different PAC products in an effort to improve contaminant removal at identical contact times and the sharing of information between companies regarding the outcome of these trials is encouraged. The verification and optimisation of applied PAC dose through live monitoring and offline laboratory methods, for example jar testing, is also encouraged.

Disinfection control

There were several events in Wales in 2024 which involved the compromising of disinfection processes through unmitigated elevations in turbidity. The events at Tynywaun and Penybont works constituted both breaches of the requirements of regulation 26 and of company disinfection strategies. The sources of this turbidity included variously the mobilisation of sediments within, and the ingress of surface water into, disinfection process assets. The absence of appropriate risk assessments, adequate asset maintenance and redundancy, sufficient water quality monitoring equipment, run to waste facilities and sufficient network resilience all contributed to the impact of these events. Site control systems should be configured to ensure failures of disinfection processes and equipment are apprehended and controlled at the earliest opportunity. Systems to contain and dispose of undisinfected water should also be carefully considered in the design of these systems where possible. Deficiencies in the site-specific risk assessments and disinfection policies have been identified during different audits conducted in 2024. For example, the treatment performance requirements for viruses and Cryptosporidium had been assessed in some analyses but not those required for bacteria. Whilst conservative performance requirements had been applied it is important that companies assess the risks and control measures in place at works for each pathogen group listed in the Regulations.